Construction Blog

Best practices

| 19.11.20 |5

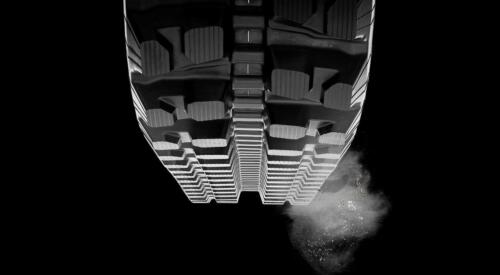

Operation, maintenance and storage tips for your construction tracks this winter

Best practices

| 10.07.20 |22

Construction tracks basics: 9 questions to master rubber tracks

Best practices

| 28.05.20 |4

Telehandler tire solutions for rental fleets: should you choose solid or foam-filled?

Best practices

| 03.07.17 |1

7 Tips for Construction users

Best practices

| 05.06.17 |1

Minimizing skid steer tire wear and premature disposal

Best practices

| 31.05.17 |3

Maintenance tips to optimize track life for your track loader

Best practices

| 18.10.16 |0

Camso OTT for Skid Steers

Best practices

| 15.09.16 |1

What to consider when choosing skid steer tires

Best practices

| 24.08.15 |0

Choosing the right tire for scrap yards

Best practices

| 24.08.15 |0