Telehandler tire solutions for rental fleets: should you choose solid or foam-filled?

Being a rental fleet manager can be quite challenging, especially when it comes to ensuring all machines are up and running. On one hand you want to choose the right components to maximize your machines’ lifespan and profitability, and on the other you need to while keep your clients satisfied.

Tires have a tremendous impact on machine performance, safety and uptime. Selecting the right tire to meet the specific requirements of each piece of machinery can quickly become a headache: as the manager of a rental company, you don’t necessarily always have visibility over your clients’ applications or the surfaces they’re working on. The wrong tire solution can often translate into downtime issues, which are a pain for both the end-user and your rental shop.

Telescopic handlers (telehandlers) are no stranger to this challenge. They must be fitted with tires that offer excellent stability given the applications they work in, lifting heavy loads and reaching high points often on unstable or unfinished surfaces. Although they might all look the same to the untrained eye, there are many different tire solutions available on the market, and multiple elements to take into account when choosing a product.

There are three different tire technologies currently available on the market for telehandlers: industrial pneumatics (radial and bias), foam-filled pneumatics and solids. For rental fleets, it can be hard to identify which tire technology to choose to both optimize uptime and get the best return on investment.

While the difference between pneumatics and solids is quite easy to understand, what is the difference between solid and foam-filled tire solutions? And what should rental companies take into account when choosing products to equip their machines? Here are 7 factors to look at for telehandler tires:

- Tread life: Many attributes of a tire can be differentiating factors when looking at overall tread life. As a general rule, solid tires will normally have a harder rubber compound and more tread depth, which equate to longer tread life.

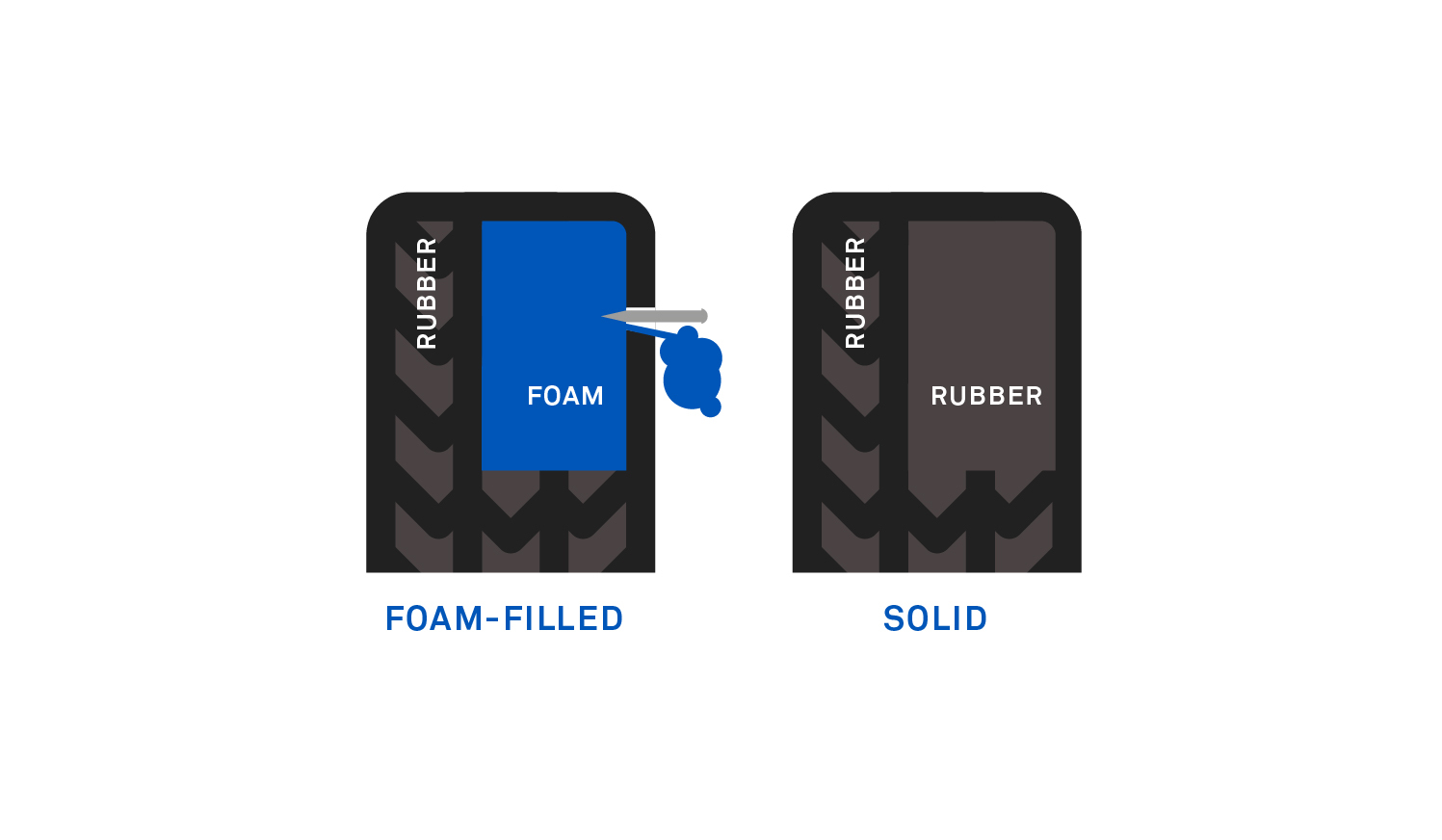

- Resistance to cuts and chunking: Foam-filled tires have a similar resistance to cuts and chunking as pneumatic tires since their outside is literally the same – the main difference being the foam inside the tire. Solids are highly resistant to cuts and chunking and should be considered in tougher applications. As mentioned before, since a rental manager cannot be aware of all client applications, we typically recommend to use a solid tire for maximum safety, stability and durability.

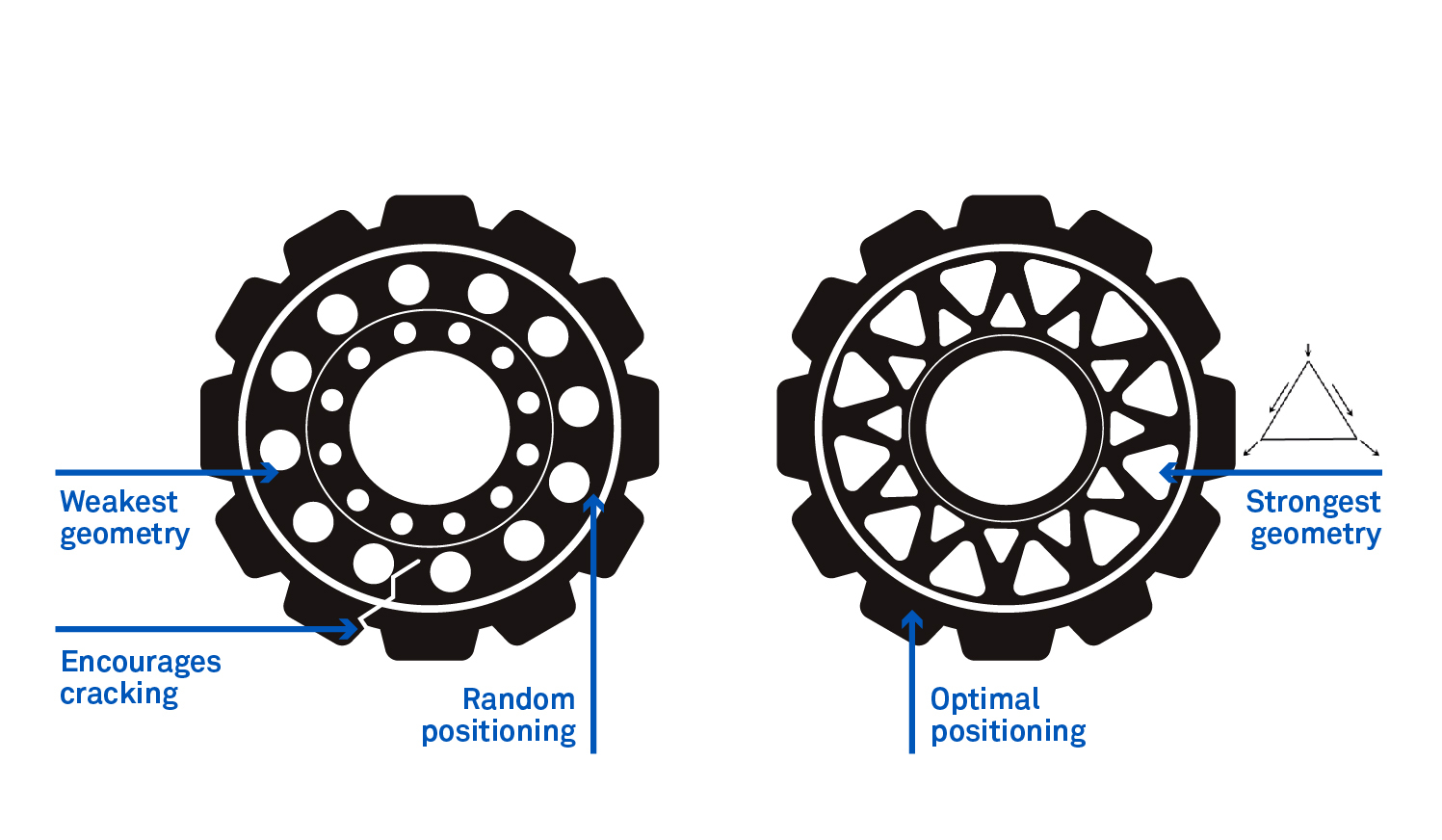

- Overall comfort: Foam-filled tires typically offer the most comfortable ride, although they do bounce a bit more than solids. As technology evolves, solids with aperture design are becoming more and more comfortable. It’s important to make sure the design offers a durable solution with maximum comfort: look for tires with triangular apertures, which don’t tend to crack as fast as round ones.

- Stability: While both foam-filled and solid tires offer both very good stability, solids provide a better weight distribution under loads. This is a big plus given the purpose of telehandlers.

- Soft surface traction: If we compare identical tread patterns and tread depths, foam-filled assemblies would provide better soft surface traction since they act more like a pneumatic tire when it comes to footprint. Once again, this ties back to knowing and understanding end-user application.

- Sidewall and tread impact resistance: Solid tires offer maximal impact resistance for both the sidewall and the tread, as their rubber compound is harder. Foam-filled pneumatic tires can be punctured by metal or rocks. In the case where a very severe cut occurs, foam may squeeze out of the tire and cause unpredicted downtime.

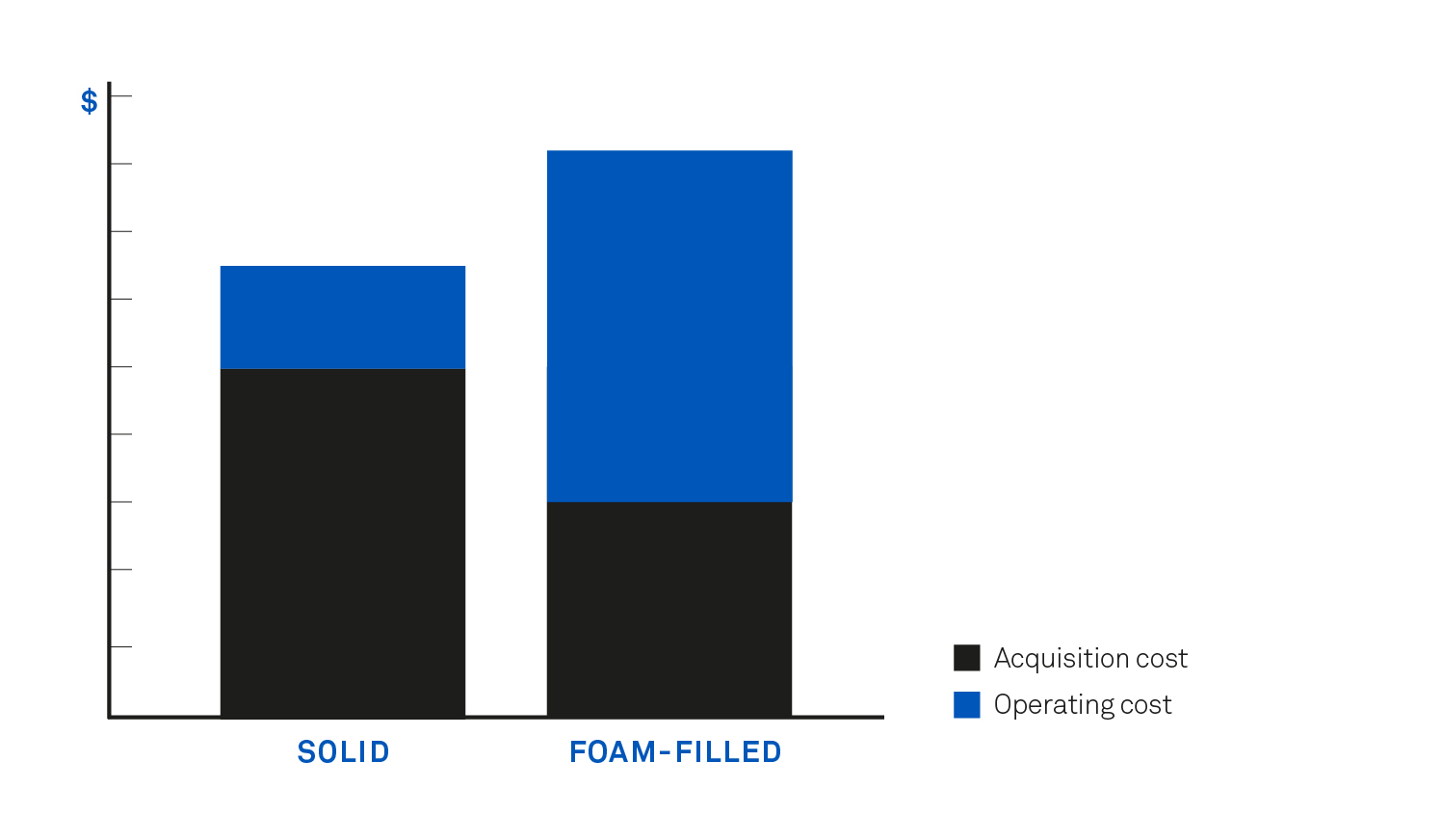

- Overall cost: Although solid tires generally have a higher upfront cost, they happen to reduce spendings throughout your machine’s life. The cost difference can vary from 15% to 40% depending on the performance required. Given that solids are fully puncture-resistant, have a better resistance to cuts and chunking, in addition to offering longer tread life, they provide a better overall solution to optimize profitability and productivity. They also offer a more predictable option, which is great for rentals.

At the end of the day, remember that your dealer is the best partner to answer your requirements and point you towards the right solution for your fleet: they have a global vision that will take into account the different variables in the equation.

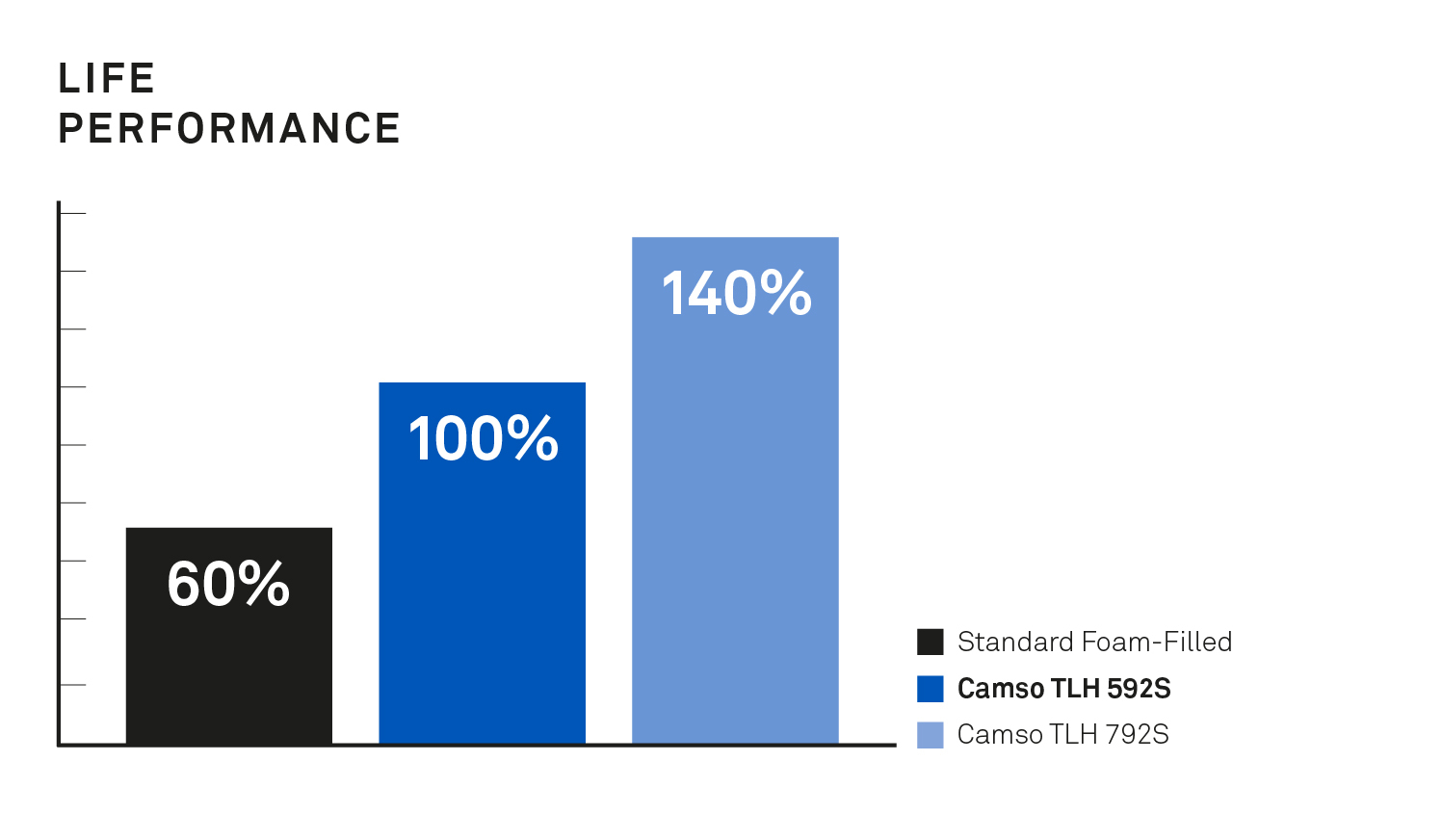

At Camso, we offer a wide range of construction solutions that have been engineered to meet the challenges of the rental industry. Our technologies for telehandlers include solids, pneumatics, and foam-filled solutions. The brand new Camso TLH 592S, a mid-range solid replacement tire for telehandlers, extends our solid telehandler tire range, alongside with the Camso TLH 792S, our toughest, longest lasting solution.