ATV / UTV

|

Best practices

|

11.10.23

Tips for adjusting and repairing track systems during riding season

Most folks in the Camso Powersports community end up clocking a fair number of hours out on tough terrains with their tracked UTV or ATV. This means they can expect their track system to need a few adjustments and repairs from time to time during the riding season.

The best way to keep your track system in prime condition month after month is to check it after each ride and make any necessary adjustments right away – just like you do with your car. That way, your tracked side-by-side will always be ready to tackle the playgrounds wherever you are.

In this article, our experts explain what to look for, what to adjust, and what to repair on your Camso UTV 4S1 track system when needed during your riding season. Maintenance tasks may vary depending on your vehicle and track system model. Always follow your Owner Manual for specific guidelines.

Keep in mind that the more you use your track system, the more you’ll need to do regular maintenance on it. The 3 most important components to pay attention to are the wheels, the bearings, and the rubber track.

The best way to keep your track system in prime condition month after month is to check it after each ride and make any necessary adjustments right away – just like you do with your car. That way, your tracked side-by-side will always be ready to tackle the playgrounds wherever you are.

In this article, our experts explain what to look for, what to adjust, and what to repair on your Camso UTV 4S1 track system when needed during your riding season. Maintenance tasks may vary depending on your vehicle and track system model. Always follow your Owner Manual for specific guidelines.

Keep in mind that the more you use your track system, the more you’ll need to do regular maintenance on it. The 3 most important components to pay attention to are the wheels, the bearings, and the rubber track.

01.

How to inspect and adjust the wheels of your track system

1. Inspect the track system’s wheels and moving parts. Make sure they are free and not frozen or that there’s no mud caked on the frame.

2. Verify wear on wheels, especially on the interior guidance strip. Replace the damaged wheel if the inner surface is perforated or when the wheel’s rolling band narrows to a width of less than 45 mm. An excessively worn wheel will not offer enough support to guide the track.

2. Verify wear on wheels, especially on the interior guidance strip. Replace the damaged wheel if the inner surface is perforated or when the wheel’s rolling band narrows to a width of less than 45 mm. An excessively worn wheel will not offer enough support to guide the track.

Camso Pro Tips:

Clean your track system after every ride.

If your track system is covered with snow, store it in a heated garage to help the ice melt. Ice normally breaks off as you ride, but if needed you can also use a wood stick to remove it without damaging your track system.

If your track system is caked in mud and you want to clean it with a pressure washer, proceed with care. You need to keep the water stream away from the wheels and hub bearing seals and the rubber caps.

If your track system is covered with snow, store it in a heated garage to help the ice melt. Ice normally breaks off as you ride, but if needed you can also use a wood stick to remove it without damaging your track system.

If your track system is caked in mud and you want to clean it with a pressure washer, proceed with care. You need to keep the water stream away from the wheels and hub bearing seals and the rubber caps.

02.

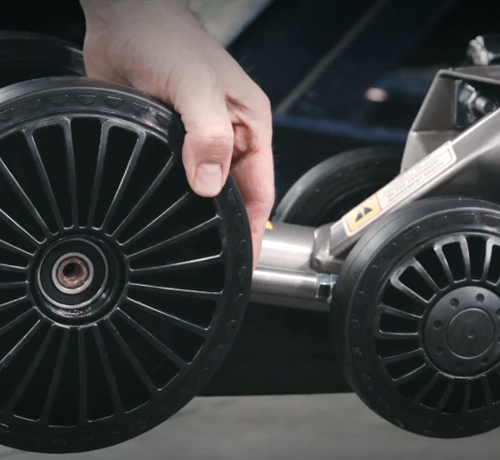

How to remove a wheel from a track system

Sometimes you must remove a wheel if the track slips off the system or you need to replace the bearings. To change a wheel, you’ll need a wrench or the Camso extractor tool. It’s designed specifically for Camso ATV T4S track system and simplifies removal.

Need the Camso extractor tool? Order it here.

.

The wheels on the Camso UTV 4S1 and Camso X4S are bolted on, so you can use either the extractor tool or a wrench.

See how to fix a broken wheel on Camso UTV 4SI

Need the Camso extractor tool? Order it here.

.

The wheels on the Camso UTV 4S1 and Camso X4S are bolted on, so you can use either the extractor tool or a wrench.

See how to fix a broken wheel on Camso UTV 4SI

03.

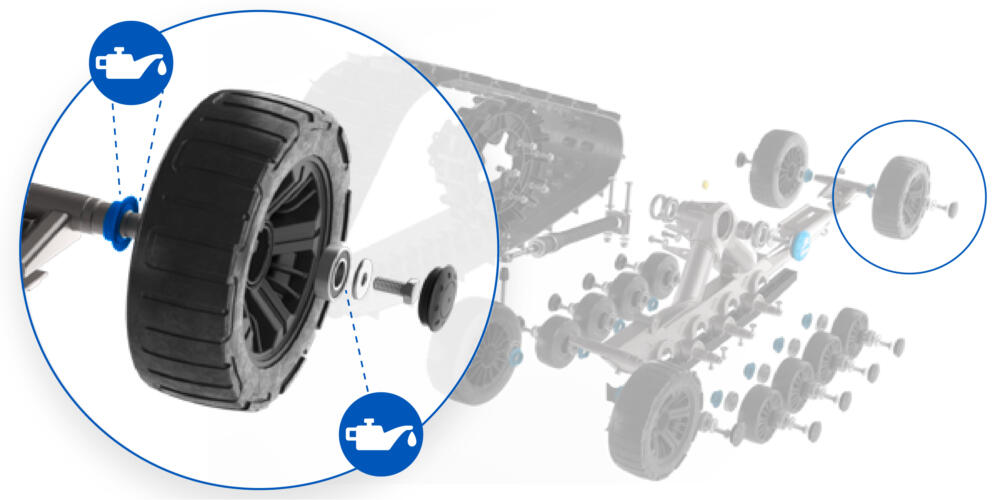

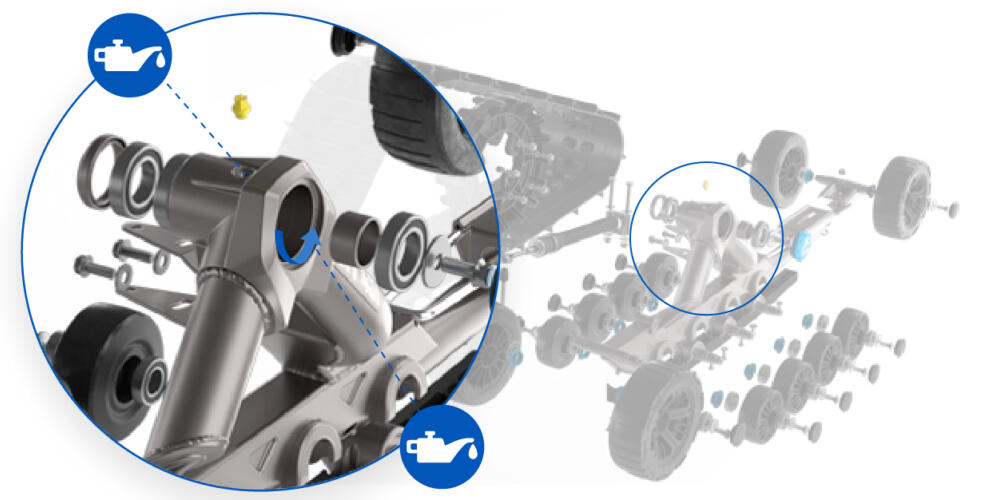

How to inspect and replace the wheel bearings on your track system

All Camso track systems are assembled with sealed bearings, which makes the tracks more durable. Careful inspection and maintenance of bearings will help prevent damage to your track system, extending its life and durability.

Check the wheel bearings for restriction, noise, or abnormal play in rotation. Replace a bearing if it shows any of these defects.

The Camso ATV T4S has its bearings molded into the wheels. If replacement is needed, you’ll have to replace the entire wheel. For the Camso X4S and Camso UTV 4S1, just the bearings can be replaced in the case of wear.

To replace the wheel bearings, follow these steps:

1. Remove the wheel with the Camso extractor tool when needed.

2. Inspect the wheel bearings for restriction, noise, or abnormal play in rotation.

3. Clean the wheel shaft and apply 3 to 3.5 cc of grease on the wheel seal’s V-shaped groove and 1 to 1.5 cc on the wheel shaft, over its entire circumference (360°) and width.

4. Install new wheel bearings.

5. Apply thread locker on the wheel bearing screw as identified in the Owner Manual.

Check the wheel bearings for restriction, noise, or abnormal play in rotation. Replace a bearing if it shows any of these defects.

The Camso ATV T4S has its bearings molded into the wheels. If replacement is needed, you’ll have to replace the entire wheel. For the Camso X4S and Camso UTV 4S1, just the bearings can be replaced in the case of wear.

To replace the wheel bearings, follow these steps:

1. Remove the wheel with the Camso extractor tool when needed.

2. Inspect the wheel bearings for restriction, noise, or abnormal play in rotation.

3. Clean the wheel shaft and apply 3 to 3.5 cc of grease on the wheel seal’s V-shaped groove and 1 to 1.5 cc on the wheel shaft, over its entire circumference (360°) and width.

4. Install new wheel bearings.

5. Apply thread locker on the wheel bearing screw as identified in the Owner Manual.

Camso Pro Tips:

Use grease designed for use in cold temperatures and wet conditions.

At every maintenance interval, pour 5 cc of oil under the wheel caps and between the wheel bearings to extend the wheel bearing life.

At every maintenance interval, pour 5 cc of oil under the wheel caps and between the wheel bearings to extend the wheel bearing life.

04.

How to lubricate the hub bearings

Apply 1.5 to 2 cc of grease evenly between the hub seal lips over the entire circumference (360°).

We recommend applying 8 to 12 cc of SAE 80W-90 through the hole on top of hub housing to lubricate the hub. Quantity of oil may vary according to your track system model (refer to your Owner Manual).

We recommend applying 8 to 12 cc of SAE 80W-90 through the hole on top of hub housing to lubricate the hub. Quantity of oil may vary according to your track system model (refer to your Owner Manual).

05.

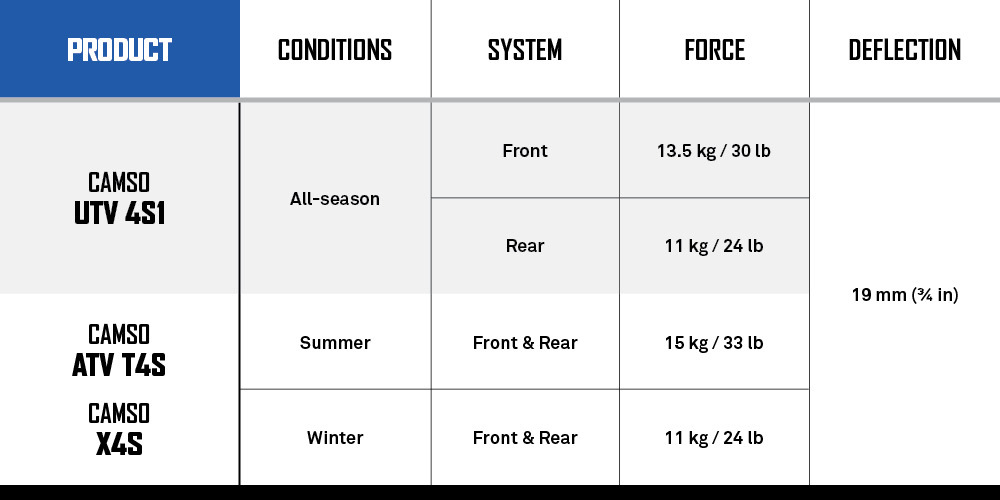

How to inspect and adjust the rubber track on your track system

Camso rubber tracks are extremely durable – even when ridden in extreme conditions. But rare cases, you may have to change your track. The good news is that you can replace just the track on the system.

Here are the basic adjustments you should regularly do on your rubber track.

Inspect and adjust the track tension as needed. This is very important for proper vehicle performance and your own safety. To properly adjust your track system’s tension, you’ll need the Camso track tension testing tool. Don’t have this tool? Order it here.

To adjust track tension, follow these steps :

1. Loosen the track tensioner assembly bolt.

2. Adjust the track tension by turning the tension adjustment bolt clockwise or counterclockwise and measure with the Camso track tension testing tool.

3. Follow the table for recommended force to apply and deflection to occur to set the right track tension according to your tracks model.

Inspect and adjust the track tension as needed. This is very important for proper vehicle performance and your own safety. To properly adjust your track system’s tension, you’ll need the Camso track tension testing tool. Don’t have this tool? Order it here.

To adjust track tension, follow these steps :

1. Loosen the track tensioner assembly bolt.

2. Adjust the track tension by turning the tension adjustment bolt clockwise or counterclockwise and measure with the Camso track tension testing tool.

3. Follow the table for recommended force to apply and deflection to occur to set the right track tension according to your tracks model.

Camso Pro Tips:

Keep the rubber track at the correct tension. This will ensure better traction, a smoother ride, and better fuel economy.

Track tension set too low can lead to derailing and drive “ratcheting”.

Track tension set too high can lead to premature wear on the system’s components.

Track tension set too low can lead to derailing and drive “ratcheting”.

Track tension set too high can lead to premature wear on the system’s components.

06.

How to reinstall a track that slips off the system while driving

1. Back up the track tensioner.

2. Remove the outside idler wheel at the tensioner position. (It will make it a lot easier to put the track back on the system.)

4. Put the track back on the system.

5. Reinstall the wheel.

6. Put the tension back on.

See our how-to-video: Top 5 tips for track systems (See 2 min 43 seconds for how to reinstall a track that slips off the system).

2. Remove the outside idler wheel at the tensioner position. (It will make it a lot easier to put the track back on the system.)

4. Put the track back on the system.

5. Reinstall the wheel.

6. Put the tension back on.

See our how-to-video: Top 5 tips for track systems (See 2 min 43 seconds for how to reinstall a track that slips off the system).

07.

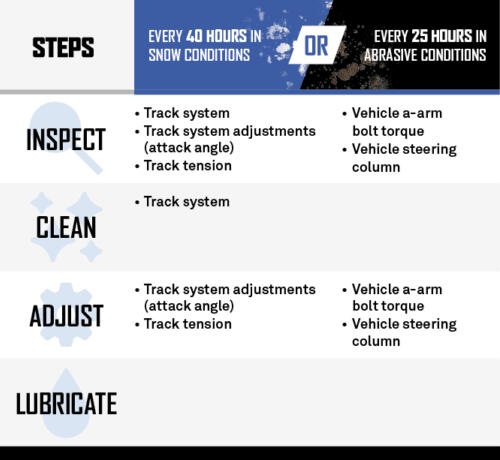

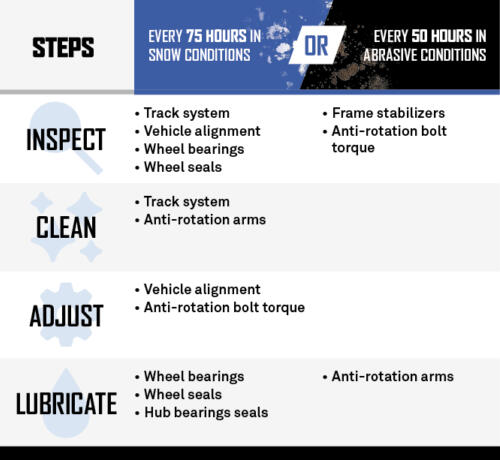

What track system maintenance to perform after more than 25 hours of riding

In addition to the routine adjustments and repairs track system owners should do throughout the riding track system, mechanic fans can also perform more thorough maintenance on a periodic basis.

Here’s a quick checklist of the system maintenance you or your dealer should perform based on usage intervals and terrain conditions.

Here’s a quick checklist of the system maintenance you or your dealer should perform based on usage intervals and terrain conditions.

You can also find complete & personalized maintenance instructions for your specific Camso track system and vehicle in your Owner's Manual.

Follow these regular maintenance tips and your Camso track system will keep you happily tearing up the trails whenever the mood strikes. Remember to tag us on social during your outdoor adventures!

Want more tips on track system maintenance? Check out our tracked ATV/UTV maintenance guide.

Get tools & replacement parts from your Camso dealer.

Follow these regular maintenance tips and your Camso track system will keep you happily tearing up the trails whenever the mood strikes. Remember to tag us on social during your outdoor adventures!

Want more tips on track system maintenance? Check out our tracked ATV/UTV maintenance guide.

Get tools & replacement parts from your Camso dealer.