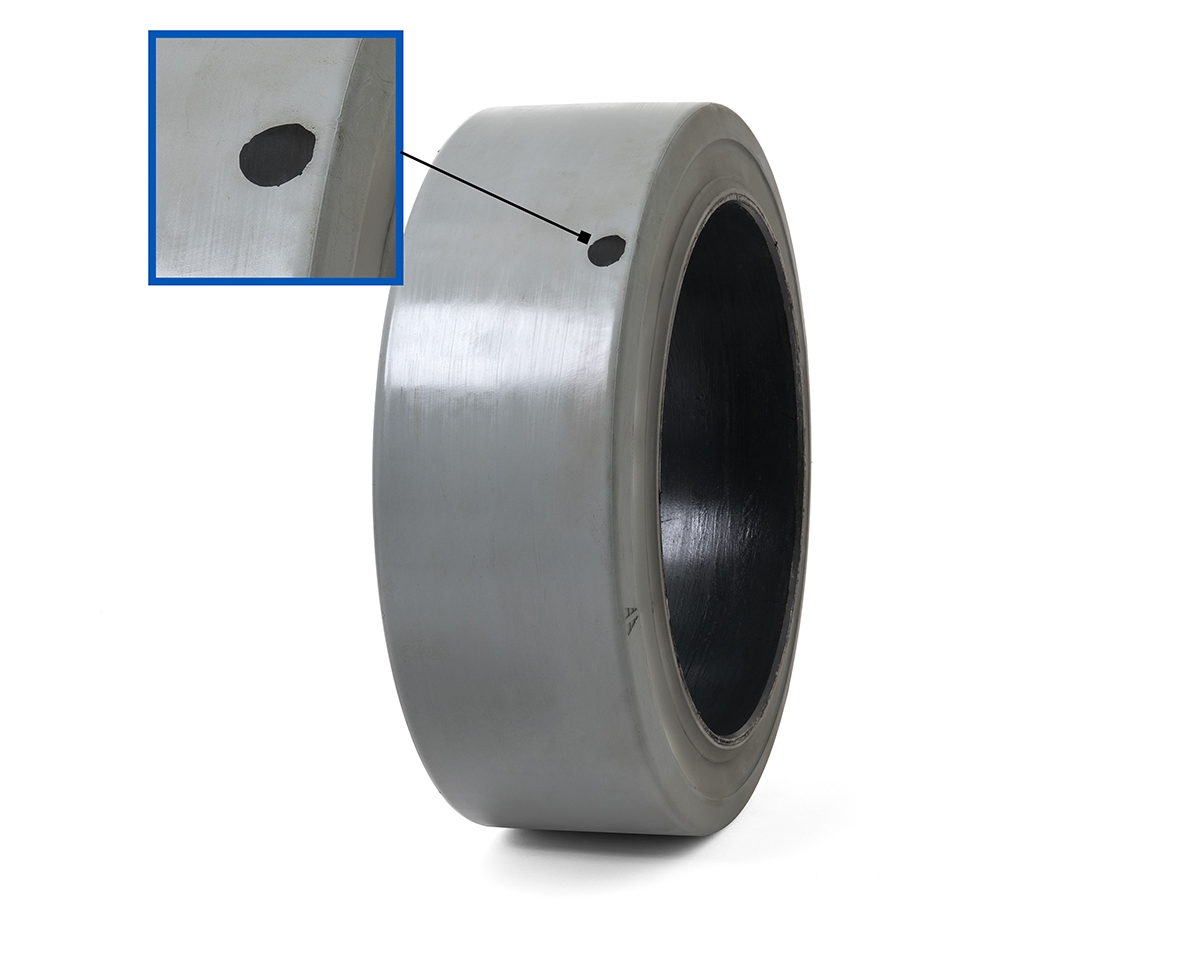

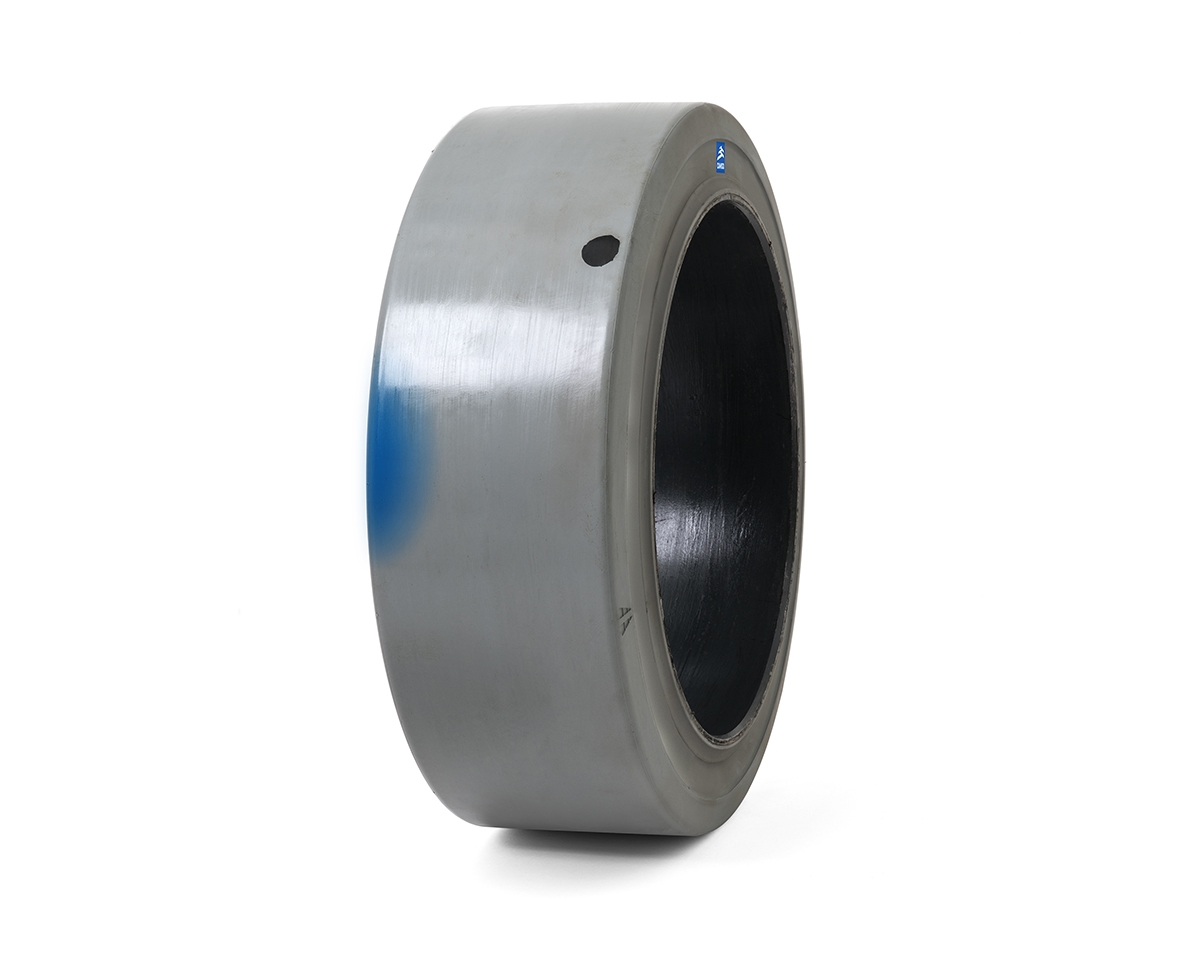

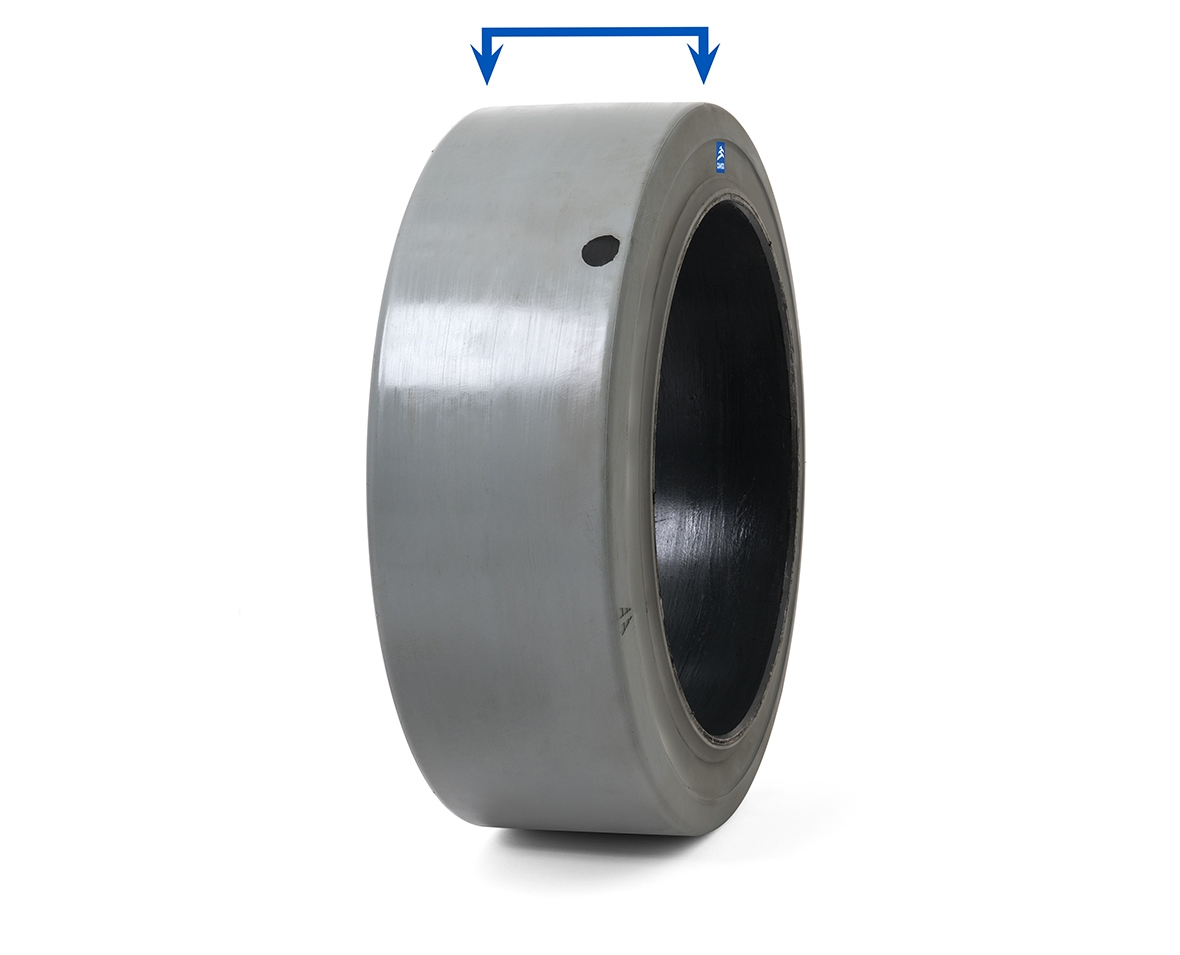

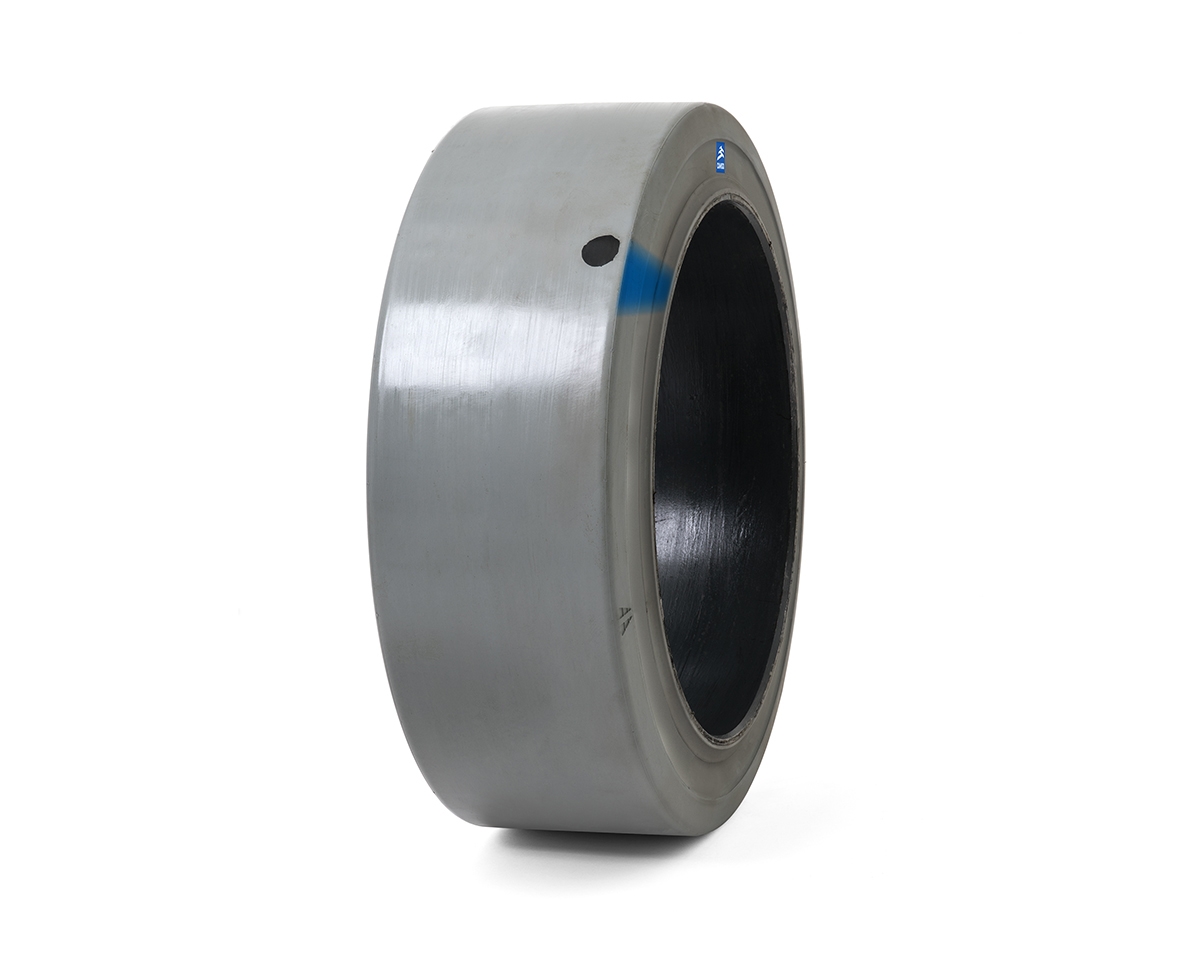

Solideal PON 775 NMAS

Engineered to prevent static shocks and provide the best performance of heat resistance, energy efficiency and long-lasting life in high intensity applications.

COMFORT

100%

ENERGY SAVING

100%

PONCTURE RESISTANCE

100%

TIRE LIFE

100%